Exploring the Versatility of Stainless Steel Bellows

Stainless steel bellows are indispensable in various industrial applications where temperature, pressure, or the nature of the media precludes the use of rubber bellows. Constructed from thin-walled tubes, the number of convolutions determines the extent of movement they can accommodate. This article delves into the different types of stainless steel bellows, their specific applications, and the customisation options available to meet unique operational requirements.

The Fundamentals of Stainless Steel Bellows

Stainless steel bellows handle extreme conditions. Unlike rubber bellows, they can withstand high temperatures, substantial pressures, and aggressive media without degrading. The convolutions in these bellows are crucial; they determine the flexibility and range of motion.

Additional bellows can be installed for greater movement requirements, or an alternative system design must be employed. Each stainless steel bellow meets specific design criteria, including length, pressure rating, end termination, and movement requirements. This customisation ensures that the bellows meet the exact needs of each expansion problem.

Types of Stainless Steel Bellows

Axial Expansion Bellows

Axial expansion bellows absorb thermal expansion in straight pipe runs. These bellows are typically used in systems operating below 10 bar pressure and must be between two anchor points with sufficient guides along the entire pipe length. This setup ensures that thermal expansion is evenly absorbed, preventing undue stress on the piping system; for example, in a heating system where pipes expand and contract with temperature changes, axial bellows can prevent the pipes from buckling or cracking. They are essential for maintaining the integrity and longevity of the piping system under varying thermal conditions.

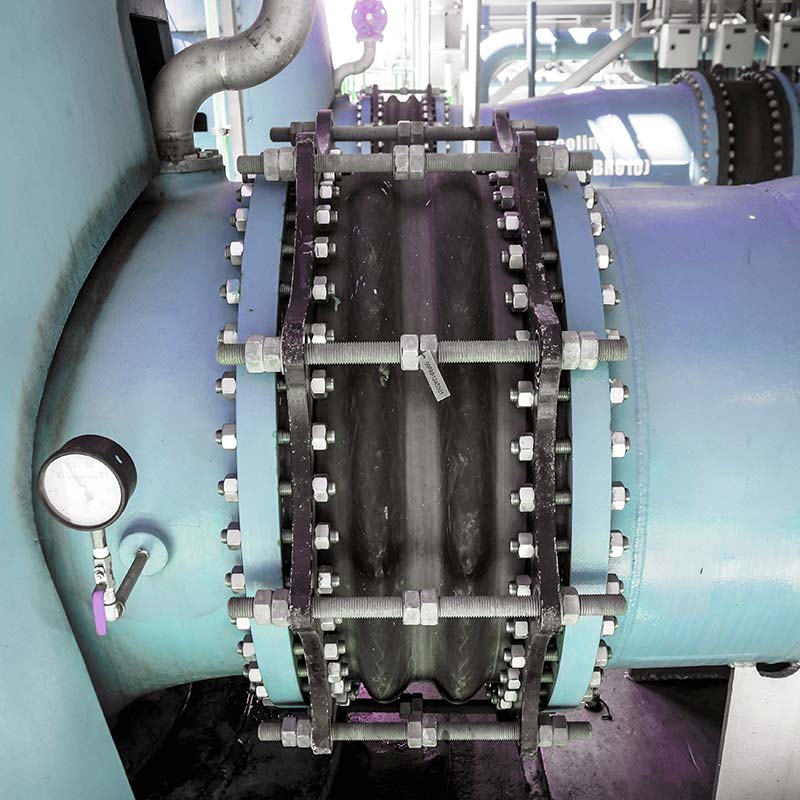

Double-Tied Bellows

Double-tied bellows are positioned at a 90-degree angle to the main pipe run and designed to absorb thermal expansion in a lateral plane, offering greater movement capabilities in two lateral planes. These units also accommodate some axial movement, making them versatile for applications where both lateral and axial movements.

In industrial setups where pipes might shift due to machinery vibrations or ground movements, double-tied bellows ensure that these shifts do not compromise the system’s integrity. They provide flexibility and resilience, essential for maintaining continuous operations in dynamic environments.

Double-Hinged Bellows

Double-hinged bellows, like double-tied bellows, are designed to absorb large movements. However, due to the hinge brackets, they allow lateral movement in only one plane; these systems are ideal for high-pressure applications or where standard steel bellows cannot contain forces from thermal expansion on anchor points.

In high-pressure steam systems, for example, double-hinged bellows can absorb the thermal expansion without exerting excessive force on the anchor points. This capability is critical for preventing system failures and ensuring safe operations under pressure.

Single-Hinged Bellows

Single-hinged bellows utilise a two or three-pin system to accommodate substantial expansion. They function similarly to double-hinged bellows and are well-suited for high-pressure applications. The hinge design allows for controlled movement in a specific direction, providing stability and reducing the risk of overextension.

Used in chemical processing plants, where pipes must handle significant thermal and pressure variations. The single-hinged design ensures that the expansion is controlled and does not lead to system failures.

Customisation and End Fittings

End fittings for stainless steel bellows include a range of terminations to suit different installation needs based on the application’s specific requirements. Common end fittings include:

- Fixed or Swivel Flanges: These flanges provide secure connections and accommodate various pipe sizes.

- Stub Pipes: For welding directly to the existing piping system, offering a seamless integration.

- BSP Male and Female Threads: These threads are suitable for systems that require threaded connections and provide installation flexibility.

- Copper Stubs: These are for applications where compatibility with copper piping is required.

The choice of end fittings is crucial for ensuring the bellows integrate into the existing system. Each fitting type offers unique benefits, and selecting the right one can enhance the system’s overall efficiency and reliability.

Practical Applications of Stainless Steel Bellows

High-Temperature Environments

Stainless steel bellows, such as power plants and industrial furnaces, are indispensable in high-temperature environments. Their ability to withstand extreme heat without compromising performance makes them ideal for these applications. The seamless integration of axial or hinged bellows ensures that thermal expansion is managed effectively, preventing damage to the system.

High-Pressure Systems

In high-pressure systems, such as steam distribution networks and hydraulic systems, stainless steel bellows provide the necessary flexibility to accommodate pressure variations. Double-hinged and single-hinged bellows are particularly suited for these applications, offering controlled movement and reducing the risk of system failures.

Aggressive Media Handling

Industries that handle aggressive media, such as chemicals or corrosive gases, benefit significantly from stainless steel bellows. Stainless steel’s corrosion-resistant properties ensure that the bellows maintain their integrity even when exposed to harsh substances. This durability is essential for maintaining safe and reliable operations in chemical processing plants and similar environments.

Vibration and Misalignment Compensation

Stainless steel bellows help to compensate for vibration and misalignment in piping systems in industries where machinery and equipment generate significant vibrations that can cause misalignment in the pipes. Double-tied and single-hinged bellows effectively absorb these movements, ensuring the pipes remain aligned and operational.

Conclusion

Stainless steel bellows are versatile and essential components in various industrial applications. Their ability to withstand high temperatures, substantial pressures, and aggressive media makes them invaluable in ensuring the reliability and longevity of piping systems. Whether axial, double-tied, double-hinged, or single-hinged bellows, each type offers unique benefits tailored to specific applications.

At Flexible Connections Ltd, we pride ourselves on providing custom solutions that meet our customers’ requirements. Our range of stainless steel bellows, combined with various end fittings, ensures that we can cater to any expansion problem you may encounter. Explore our offerings today and experience the quality and reliability that our stainless steel bellows bring to your operations.

For more detailed information about our products and services, CLICK HERE!